1. Core Principle: Pressure Swing Adsorption (PSA)

A PSA oxygen generator separates oxygen (O₂) from atmospheric air using selective adsorption—a process where a porous material (“adsorbent”) traps one gas (nitrogen, N₂) under high pressure and releases it under low pressure. Since air is ~78% N₂, 21% O₂, and 1% other gases (argon, CO₂), the goal is to isolate O₂ by removing N₂.

2. Key Components

Every PSA oxygen generator has 5 essential parts, each supporting the adsorption/desorption cycle:

|

Component

|

Function

|

|

Air Compressor

|

Draws in atmospheric air and compresses it (typically 5–10 bar) to enable adsorption.

|

|

Air Pre-Filter

|

Removes dust, oil, and moisture from compressed air—these impurities damage the adsorbent.

|

|

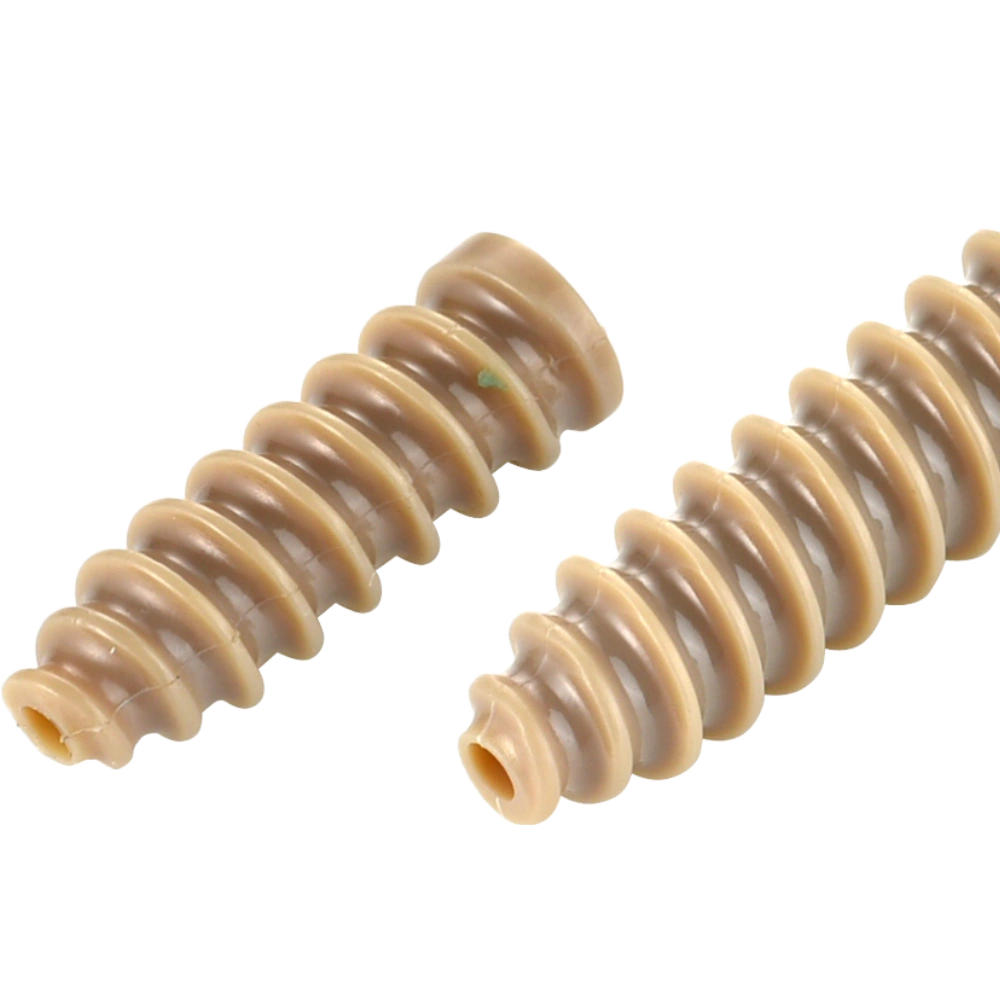

Dual Adsorption Towers

|

Two parallel towers filled with zeolite molecular sieve (the adsorbent). They alternate work to ensure continuous O₂ output.

|

|

Valve System

|

Automatically switches airflow between the two towers to control pressure (high for adsorption, low for regeneration).

|

|

Oxygen Buffer Tank

|

Stores produced O₂ temporarily to stabilize pressure and flow rate for end use (e.g., medical, industrial).

|

3. Step-by-Step Operation (Dual-Tower Cycle)

The generator uses two towers (Tower A and Tower B) that alternate between adsorption (O₂ production) and regeneration (N₂ release). A full cycle takes ~60–120 seconds.

Phase 1: Adsorption (Tower A Active, Tower B Regenerating)

- Air Input: Compressed, filtered air flows into Tower A (high pressure: 5–10 bar).

- N₂ Trapping: Zeolite molecular sieve has a strong affinity for N₂ (due to N₂’s larger molecular size and higher polarity). It adsorbs (traps) N₂ in its pores, while O₂ (smaller, less polar) passes through unimpeded.

- O₂ Collection: The pure O₂ (typically 90–95% purity; medical models reach 99.5%) flows into the buffer tank, then to the user (e.g., oxygen concentrators for patients).

- Tower B Regeneration: Meanwhile, Tower B is depressurized (to near atmospheric pressure). The low pressure reduces zeolite’s ability to hold N₂, so trapped N₂ is released (vented to the atmosphere). A small amount of pure O₂ may also be used to “purge” remaining N₂ from Tower B, speeding up regeneration.

Phase 2: Switching Cycles (Tower B Active, Tower A Regenerating)

- The valve system flips: Compressed air now flows into Tower B (starting adsorption and O₂ production), while Tower A is depressurized (releasing N₂ and regenerating).

- This alternation ensures continuous O₂ output—there is no gap in production.

4. Critical Why’s

- Why zeolite? Zeolite is a porous, aluminosilicate mineral with tiny pores (0.3–1 nm) that match N₂’s molecular size, making it highly selective for N₂ over O₂.

- Why two towers? A single tower would stop producing O₂ during regeneration. Dual towers let one produce O₂ while the other resets.

- Why pressure swing? Adsorption (trapping N₂) requires high pressure (increases zeolite’s N₂ capacity), while desorption (releasing N₂) requires low pressure (reduces capacity). The “swing” between pressures drives the cycle.

5. Typical Applications

PSA generators are used where on-site O₂ is needed:

- Medical: Home oxygen concentrators, hospital bedside units.

- Industrial: Metal cutting (oxy-fuel), wastewater treatment (aeration).

- Aquaculture: Oxygenation of fish tanks/ponds.